West Highland Way Diary

Day 5

I got my wish! Today was the best day of hiking so far!

Last night we started to get a little nervous. Don’t know how we missed this, but we started looking at what others posted about today’s hike and we saw lots and lots of stuff talking about how it was the worst day of the hike, the trail was difficult, people giving up, and we were like, oh no, how did we not know this? Oops. So starting out this morning we were pretty nervous about how the day was going to go. Turns out, it went great!

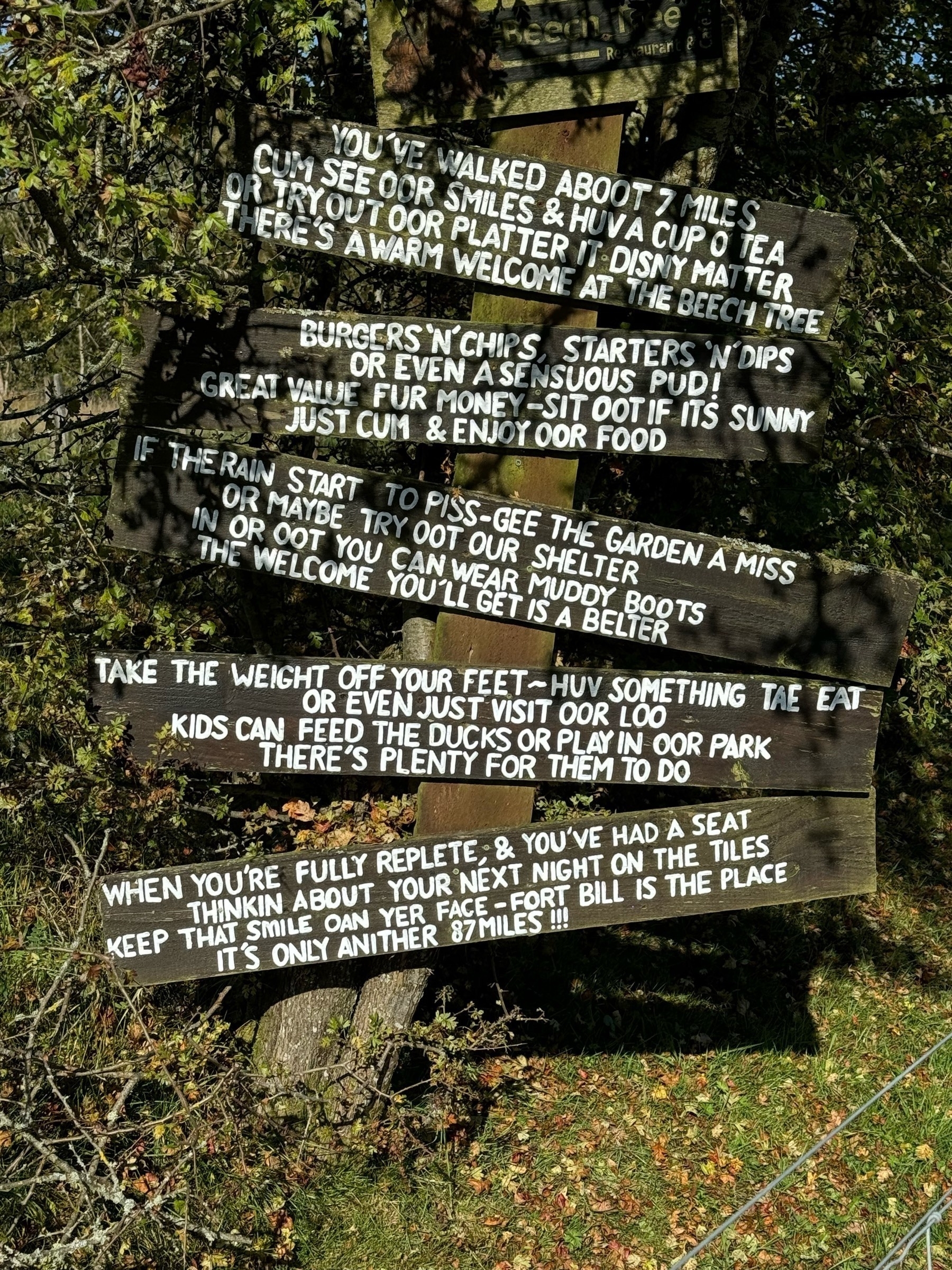

Started out easy enough and a couple of miles in we had a choice: the high road or the low road. The low road was the original Way that went down along the loch. It was described as a challenging section. The high way was added recently and stayed closer to the road and was easier. So of course we took the low road. ;)

They weren’t wrong about the challenging part. There were a lot of stone paths and steps, some climbing over boulders, walking along a path where to our left was quite the drop into the loch. But boy oh boy was it fun! This was what we were both looking forward to and we got it. After a couple of miles of this, the two paths joined up again and after several more miles we made it to Inversnaid where we stopped for lunch.

After that came the really challenging part of the walk. As one of our guide books said, the path was more obstacle course than footpath, and it was! Again we loved it. Up and down, climbing, scrambling, over fords, through creeks, everything. All of it right along Loch Lomond with absolutely gorgeous views. I wanted a wilderness hike and this portion really delivered. Eventually we got to the northern end of the loch, made our way across some fields and a small saddle and finally down into Inverarnan (which according to the locals is pronounced In-ver-RARE-ree).

Truly, this was the best hike of the trip so far. I guess Dena and I like “technical” hikes as they’re known. Tomorrow begins our hike really up into the highlands, maybe even cross some moors. Looking forward to it.

JIm